Stellar Shuttle Series Hooklift

STELLAR SHUTTLE SERIES HOOKLIFTS

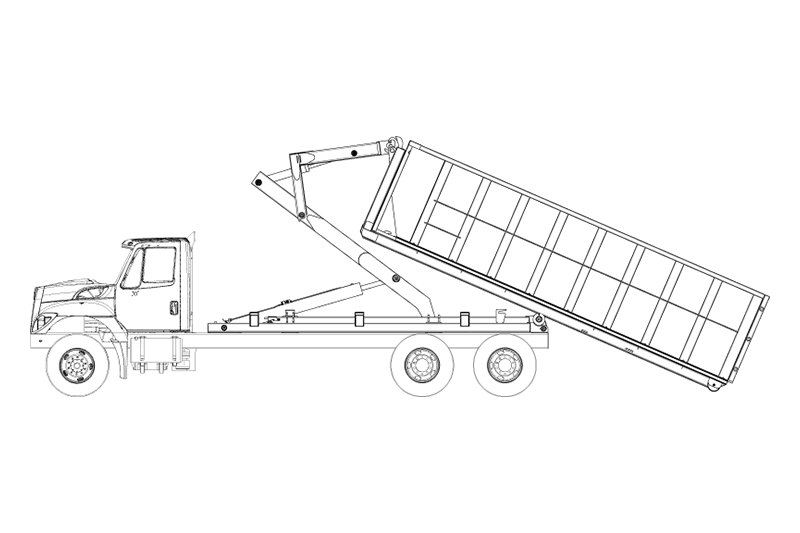

Easy to operate, packed with power and built to last, Stellar® Shuttle Series Hooklift Trucks allow one operator to load and unload or change bodies without leaving the truck cab.

Stellar Shuttle65 Hooklift

When heavy hauling is required, look to the 65,000-lb Stellar® Shuttle Hooklift for the solution. These models are designed to handle the extremely heavy loads of both on- and off-road hauling. The 65,000-lb Stellar Shuttle Hooklifts feature dual 7″ bore lift/dump cylinders to keep the overall height and total weight as low as possible. Dual rear rollers with integral rear body tiedowns are standard. Stellar 65,000-lb Hooklift Loaders are available in both on-road and extra heavy-duty off-road versions. Off-road versions feature heavy double-plate construction throughout. The rear portions of the dump section and base are constructed of 3″ thick solid steel plate. These massive hook loader machines are designed for heavy work in foundries, steel mills and scrap yards.

SHUTTLE65 HOOKLIFT BENEFITS

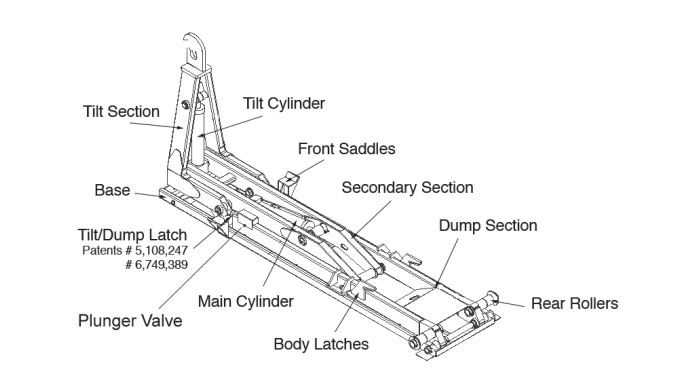

- Will accommodate bodies from 15′ to 21.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual stack-type hydraulic valve. Solenoid-activated hydraulic control valve with electric remote-control pendant is optional.

- 25-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 24 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic rotary valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Shuttle52 Hooklift

The 52,000-lb Stellar® Shuttle Hydraulic Hooklifts are the “bread and butter” models for our heavy-hauling customers. With our unique single-dump cylinder design, Stellar 52,000-lb models can provide up to a ton more net payload than most competitive hooklift and roll-off units of equal-rated capacity. The Stellar low-flow/high-pressure hydraulic system allows for weight savings in the hydraulic system as well by requiring a smaller hydraulic than competitive models. Stellar 52,000-lb Hooklift Loaders have proven themselves in some of the roughest imaginable applications, including demolition debris hauling, self-contained compactor retrieval, off- and on-road construction, agriculture and logging.

SHUTTLE52 HOOKLIFT BENEFITS

- Will accommodate bodies from 15′ up to 21.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual stack-type hydraulic valve.

- 25-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 24 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear-body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic rotary valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Shuttle40 Hooklift

The 40,000-lb capacity Stellar® Shuttle Hydraulic Hooklift Loader is one of our most popular sizes for use in the construction industry. The shorter 108-14-40 is popular when teamed with a 13′ dump body for general purpose hauling. The 138-18-40 is ideal for use with 2,500-gallon water tank, vacuum tanker or 16′ dump body. The longer 174-20-40 and 190-22-40 models are solid values for hauling larger debris boxes or transporting heavy construction equipment, such as self-contained pavers, rollers, etc.

SHUTTLE40 HOOKLIFT BENEFITS

- Will accommodate bodies from 12′ to 21.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual hydraulic valve.

- 25-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 24 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic rotary valve to prevent front tilt movement when the dump frame is raised.

- Pre-lubricated greaseable bushings used at pivot points.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Shuttle34 Hooklift

With a 34,000-lb capacity and a 54″ hook height, this model of hooklift was designed to facilitate hooklift owners who need a greater load capacity. Even with increased capacity this hooklift does not require changing the hook height on existing containers. The 54″ hook height can accommodate containers used by 20,000-lb Stellar® Hooklifts. The 138-18-34 can also accommodate most competitive hooklift latches.

SHUTTLE34 HOOKLIFT BENEFITS

- Will accommodate bodies from 15′ to 17.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual hydraulic valve.

- 25-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 24 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear-body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic rotary valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Shuttle32 Hooklift

Based on our successful 40,000 and 52,000-lb capacity models, the 32,000-lb series is the right choice for those who are hauling a consistent weight or aiming for lighter loads. The 32,000-lb capacity Stellar® Hydraulic Hooklifts are designed for use with a heavy single rear axle or light tandem axle truck chassis. All Stellar 32,000-lb capacity hooklift loaders feature the taller 61.75″ tall hook height, a feature common to all heavier-capacity Stellar Hooklift Loaders. The 108-14-32 is specially designed for municipal use with a short body. For a heavy, single rear-axle truck, the 108-14-32 offers maximum loading capacity with a short, highly maneuverable turning radius.

SHUTTLE32 HOOKLIFT BENEFITS

- Will accommodate bodies from 12′ to 17.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual hydraulic valve.

- 25-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 24 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear-body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic rotary valve to prevent front tilt movement when the dump frame is raised.

- Pre-lubricated greaseable bushings used at pivot points.Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Shuttle24 Hooklift

Stellar designed this special hooklift from the ground up for the municipality or contractor who needs a short, maneuverable, single-axle truck with a high payload capacity. We determined through surveys of our distributors and operators that the most common body on this truck would be a dump body. Designed for a truck with a CA of 84″, this model is proving its worth across the country in tough day-in, day-out use. The 96-10-24 has since proven it is as equally suited for a salt spreader, vacuum tanker, asphalt patcher or one of many other limited-use applications.

SHUTTLE24 HOOKLIFT BENEFITS

- Will accommodate bodies from 10′ to 12.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual hydraulic valve.

- 10-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 16 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear-body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic plunger valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Shuttle20 Hooklift

Stellar’s lineup of 20,000-lb-capacity Shuttle Hooklift loaders offers the greatest selection of any hooklift manufacturer. With many different lengths available, 20,000-lb Stellar® Hooklifts cover from 102″ to 200″ cab-to-axle lengths for single rear axle truck chassis. With the broadest array of sizes, Stellar 20,000-lb models have proven their use in a wide variety of uses. From roofers to recyclers, landscapers to lumber yards, the versatile Stellar 20,000-lb models can be found in almost any application.

SHUTTLE20 HOOKLIFT BENEFITS

- Will accommodate bodies from 11′ up to 21.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual hydraulic valve.

- 10-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 16 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic plunger valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Shuttle16 Hooklift

No other hooklift manufacturer currently offers the flexibility of the Stellar® Shuttle16. The Shuttle16 can handle dump containers ranging from 8′ to 15′ and flatbeds ranging from 10′ to 16′ and has a lifting capacity of up to 16,000 lbs. It has a maximum dump angle of 50˚ to 54˚, depending on the length of body. The Shuttle16 maintains all of Stellar’s efficient operational and mechanical features such as the in-cab controls and body locks to ensure stability and secure attachment. All Stellar Hooklifts feature permanently lubricated greaseable bushings, zinc-plated pins and an efficient low-flow, high-pressure hydraulic system.

SLIDER16 HOOKLIFT BENEFITS

- Will accommodate bodies from 8′ up to 15′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls that allow for metering of the manual hydraulic valve. 10-gallon-capacity, frame-mounted oil reservoir.

- Maximum hydraulic flow is 16 gallons per minute.

- Patented dump/load interface.

- Counterbalance valves to prevent cylinder movement in case of pressure loss.

- Mechanical rear-body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic plunger valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

- Full length dump frame with front saddles to support the body during the dump mode.

- Greaseable rear load rollers.