Stellar Slider Series Hooklift

STELLAR SLIDER SERIES HOOKLIFTS

Do more with one truck. Stellar® Hooklift Trucks, Roll-Off Cable Hoist Trucks and Container Carriers are true versatile performers built for everyday duty. They can pick up, haul and place a wide range of container types and sizes, so you can get job after job after job done.

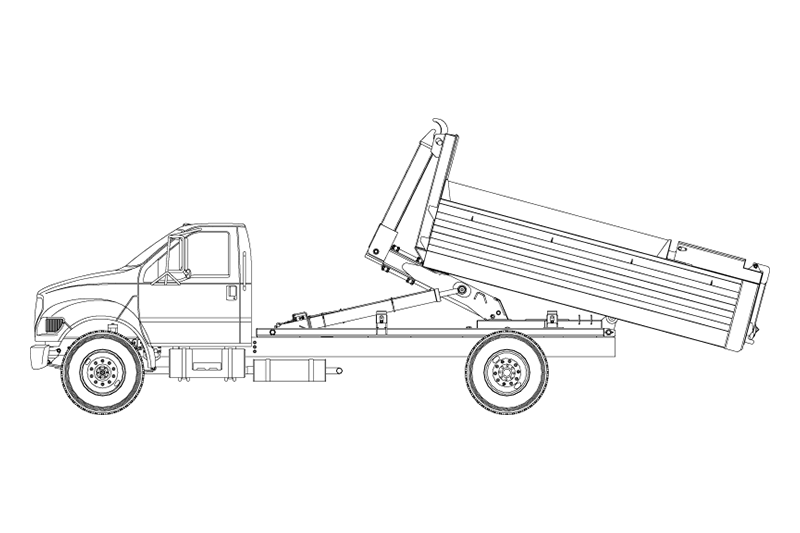

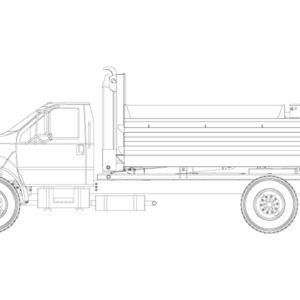

Stellar Slider65 Hooklift

Up to 65,000-lb Capacity Sliding Jib Hooklift Lift and haul the heaviest of loads in just about any application. The Stellar® Slider65 Hooklift is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with lengths ranging from 16′ (4.8 m) to 21.5′ (6.5 m) with the use of a hexagonal sliding jib. The hex jib reduces flex and provides greater structural integrity. The Slider65 can accommodate capacities up to 65,000 lbs (29,484 kg). The maximum dump angle is 50° with all hook heights. The Slider65 is available with 54″ (1,372 mm) or 61.75″ (1,568 mm) hook heights that are adjustable either manually or hydraulically.

SLIDER65 HOOKLIFT BENEFITS

- Will accommodate various hook heights on containers with adjustable hook height jibs, either with manual adjustable or hydraulic adjustable.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift. • Standard in-cab cable or air controls allow for metering of the manual hydraulic valve.

- 25-gallon frame-mounted oil tank.

- Operating pressure is 4,500 psi.

- Hydraulic flow required is 24 gallons per minute.

- Patented dump/load interface as featured on most Stellar Hooklifts.

- Hydraulic counterbalance valves prevent cylinder collapse in case of hose failure.

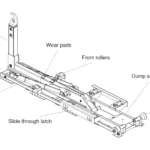

- Slide-through, rear-body tiedown latches.

- Plunger valve to prevent front jib movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

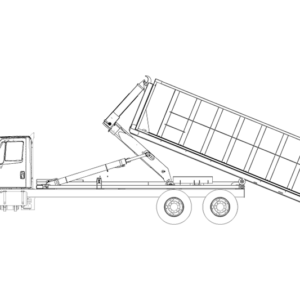

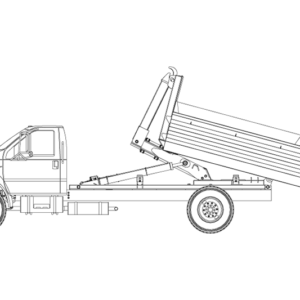

Stellar Slider50 Hooklift

Up to 50,000-lb Capacity Sliding Jib Hooklift Hauling hefty containers of concrete, waste, timber or debris? Stellar has you covered. The Stellar® Slider50 Hooklift is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with lengths ranging from 16′ (4.8 m) to 22′ (6.7 m) with the use of a hexagonal sliding jib. The hex jib reduces flex and provides greater structural integrity.The Slider50 can accommodate capacities up to 50,000 lbs (22,680 kg). The maximum dump angle is 51° with all hook heights. The Slider50 is available with 54″ (1,372 mm) or 61.75″ (1,568 mm) hook heights that are adjustable either manually or hydraulically.

SLIDER50 HOOKLIFT BENEFITS

- Will accommodate various hook heights on containers with adjustable hook height jibs, either with manual adjustable or hydraulic adjustable.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab cable or air controls allow for metering of the manual hydraulic valve.

- 25-gallon frame-mounted oil tank.

- Operating pressure is 4,500 psi.

- Hydraulic flow required is 24 gallons per minute.

- Patented dump/load interface as featured on most Stellar Hooklifts.

- Secondary speed enhancement system that reduces extended cycle time 75%.

- Hydraulic counterbalance valves to prevent cylinder collapse in case of hose failure.

- Valve bank equipped with power beyond port.

- Inside or outside bolt-on, slide-through, rear-body tiedown latches.

- Plunger valve to prevent front jib movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Slider40 Hooklift

Up to 40,000-lb Capacity Sliding Jib Hooklift Increase efficiency and productivity with the Stellar® Slider40 Hooklift. The Slider40 is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with lengths ranging from 12′ (3.6 m) to 16′ (4.8 m) with the use of a hexagonal sliding jib. The hex jib reduces flex and provides greater structural integrity. The Slider40 can accommodate capacities up to 40,000 lbs (18,144 kg). The maximum dump angle is 51° with all hook heights. The Slider40 is available with 54″ (1,372 mm) or 61.75″ (1,568 mm) hook heights that are adjustable either manually or hydraulically.

SLIDER40 HOOKLIFT BENEFITS

- Will accommodate various hook heights on containers with adjustable hook height jibs, either with manual adjustable or hydraulic adjustable.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift loader.

- Standard in-cab cable or air controls allow for metering of the manual hydraulic valve.

- 25-gallon frame-mounted oil tank.

- Operating pressure is 4,500 psi.

- Maximum hydraulic flow is 24 gallons per minute.

- Patented dump/load interface as featured on most Stellar Hooklifts.

- Hydraulic counterbalance valves to prevent cylinder collapse in case of hose failure.

- Slide-through, rear-body tiedown latches and optional inside latches.

- Plunger valve to prevent front jib movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Slider34 Hooklift

SLIDER34 HOOKLIFT BENEFITS

- Will accommodate various hook heights on containers with adjustable hook height jibs, either with manual adjustable or hydraulic adjustable.

- Transmission-mounted PTO and hydraulic pump required to power the Hooklift loader.

- Standard in-cab cable or air controls allow for metering of the manual hydraulic valve.

- 25-gallon frame-mounted oil tank.

- Operating pressure is 4,500 psi.

- Maximum hydraulic flow is 24 gallons per minute.

- Patented dump/load interface as featured on most Stellar Hooklifts.

- Hydraulic counterbalance valves to prevent cylinder collapse in case of hose failure.

- Slide-through rear-body tiedown latches, and optional inside latches.

- Plunger valve to prevent front jib movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Stellar Slider26 Hooklift

30,000-lb Capacity Sliding Jib Hooklift Achieve more picks per day for improved productivity in your daily operations. The Stellar® Slider26 Hooklift is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with lengths ranging from 12′ (3.6 m) to 16′ (4.8 m) with the use of a sliding rectangular jib. The rectangular jib reduces flex and provides greater structural integrity. The Slider26 can accommodate capacities up to 30,000 lbs (13,607 kg). The maximum dump angle is 68° with all hook heights. The Slider26 is available with 35.63″ (905 mm) or 54″ (1,372 mm) and 54″ (1,372 mm) or 61.75″ (1,568 mm) hook heights that are adjustable either manually or hydraulically.

SLIDER26 HOOKLIFT BENEFITS

- Will accommodate bodies from 12′ up to 16′ long and still retain the maximum rated dump angle on a 40″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Will accommodate various hook heights on containers with adjustable hook heights jibs, either with manual adjustable hook heights or hydraulic hook heights.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for metering of the manual hydraulic valve.

- 25-gallon frame-mounted oil tank.

- Operating pressure is 4,500 psi.

- Hydraulic flow required is 24 gallons per minute.

- Valve bank equipped with power beyond port.

- Patented dump/load interface as featured on most Stellar Hooklifts.

- Hydraulic counterbalance valves to prevent cylinder collapse in case of hose failure.

- Inside or outside bolt-on slide through rear body tiedown latches.

- Plunger valve to prevent front jib movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

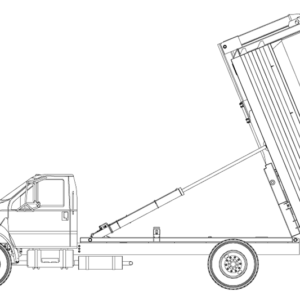

Stellar Slider20 Hooklift

20,000-lb Capacity Sliding Jib Hooklift Take your hooklift truck fleet to new heights for your business. The Stellar Slider20 Hooklift is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with lengths ranging from 13′ (3.9 m) to 18′ (5.4 m ) with the use of a sliding hexagonal jib. The hex jib reduces flex and provides greater structural integrity. The Slider20 can accommodate capacities up to 20,000 lbs (9,071 kg). The maximum dump angle is 55° with all hook heights. The Slider20 is equipped with a telescopic jib and is available with 54″ (1,372 mm) or 61.75″ (1,568 mm) hook heights that are adjustable either manually or hydraulically to allow for working with various length and hook height containers.

SLIDER20 HOOKLIFT BENEFITS

- Will accommodate various hook heights on containers with adjustable hook heights jibs, either with manual adjustable hook heights or hydraulic hook heights.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab cable or air controls allow for metering of the manual hydraulic valve.

- 10-gallon frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 16 gallons per minute.

- Valve bank equipped with power beyond port.

- Mechanical dump/load interface.

- Hydraulic counterbalance valves to prevent cylinder collapse in case of hose failure.

- Inside or outside bolt-on, slide-through, rear-body tiedown latches.

- Plunger valve to prevent front jib movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.